Week2

By Shannon MA

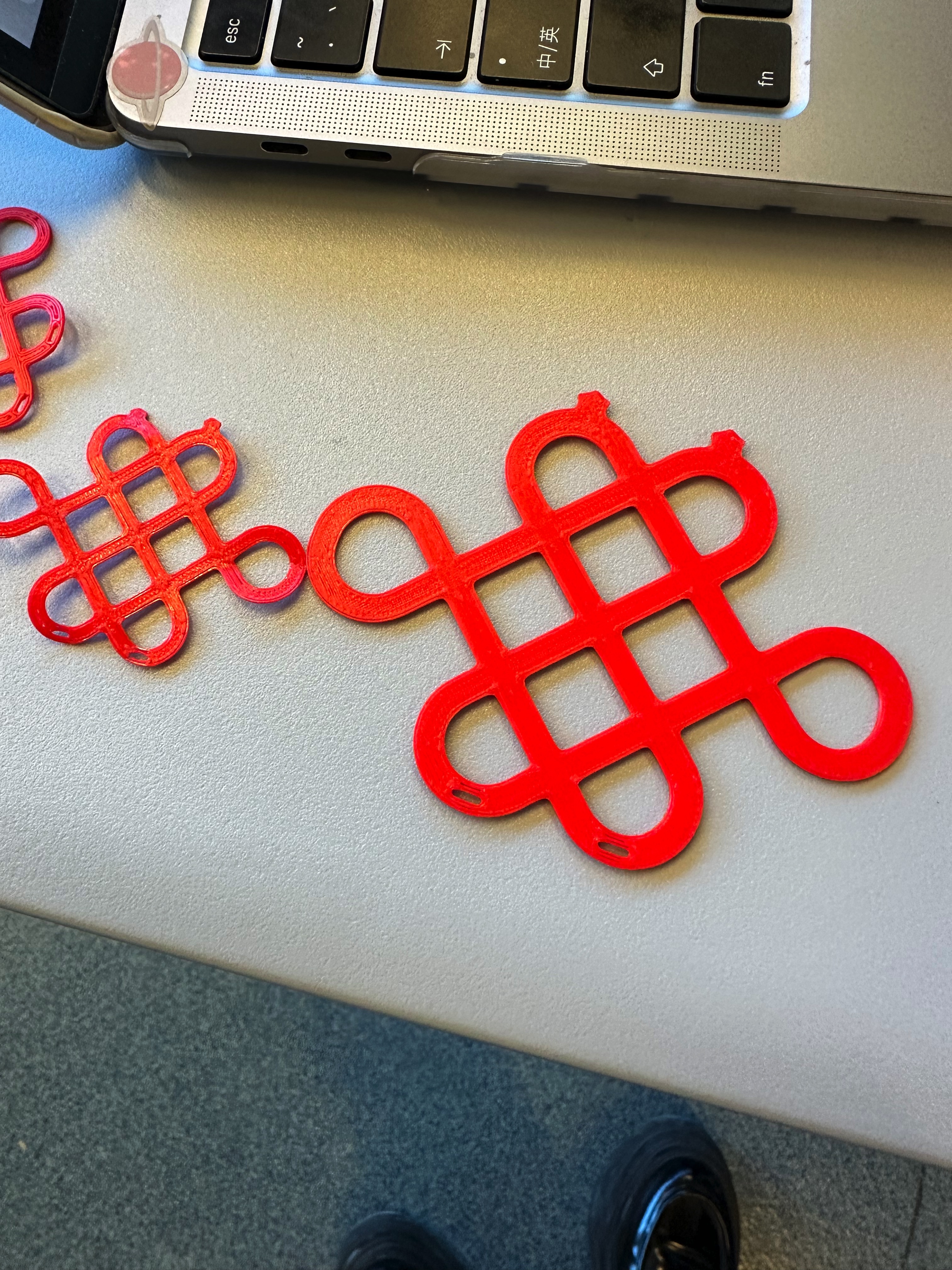

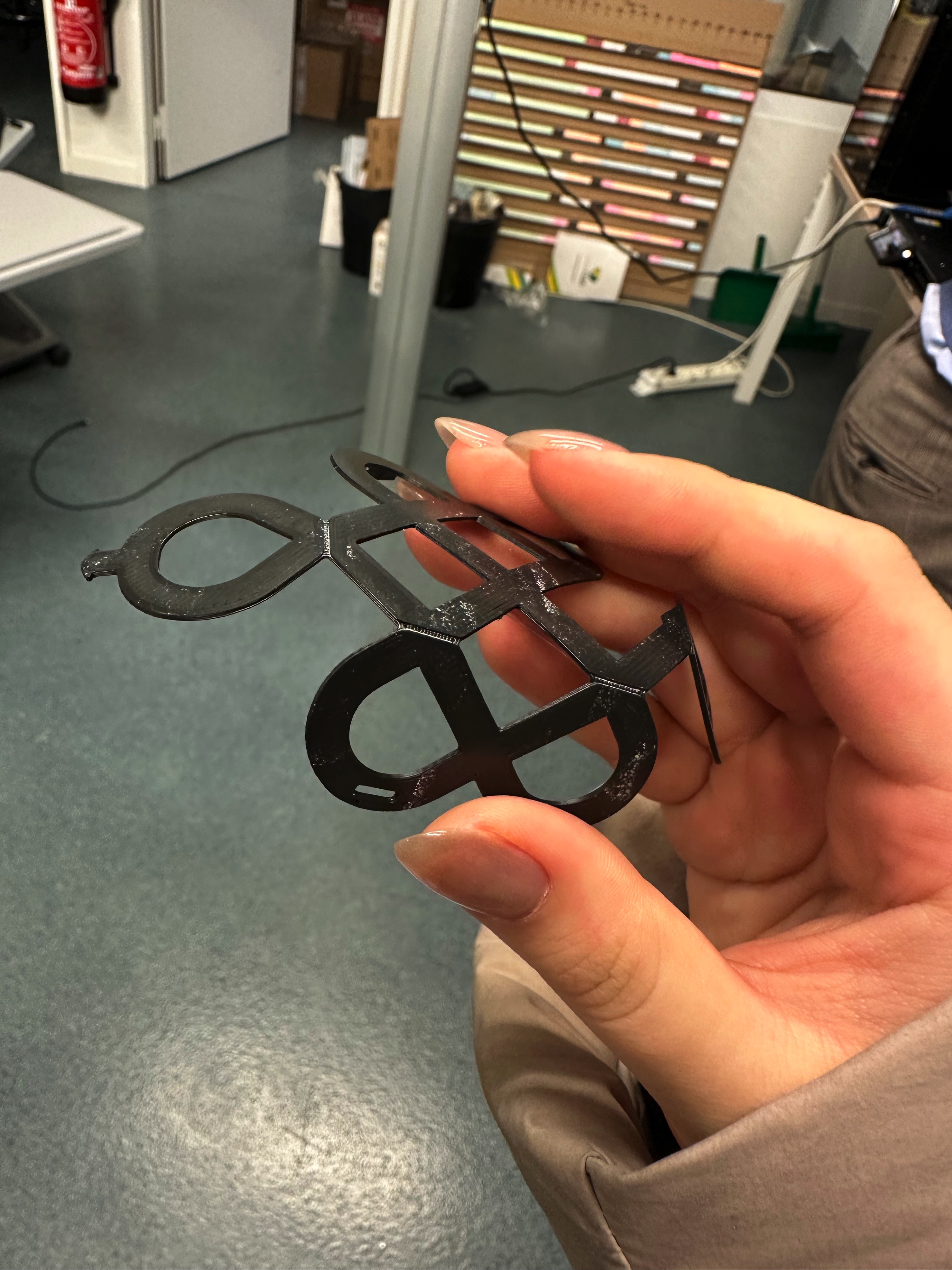

First Try of Printing

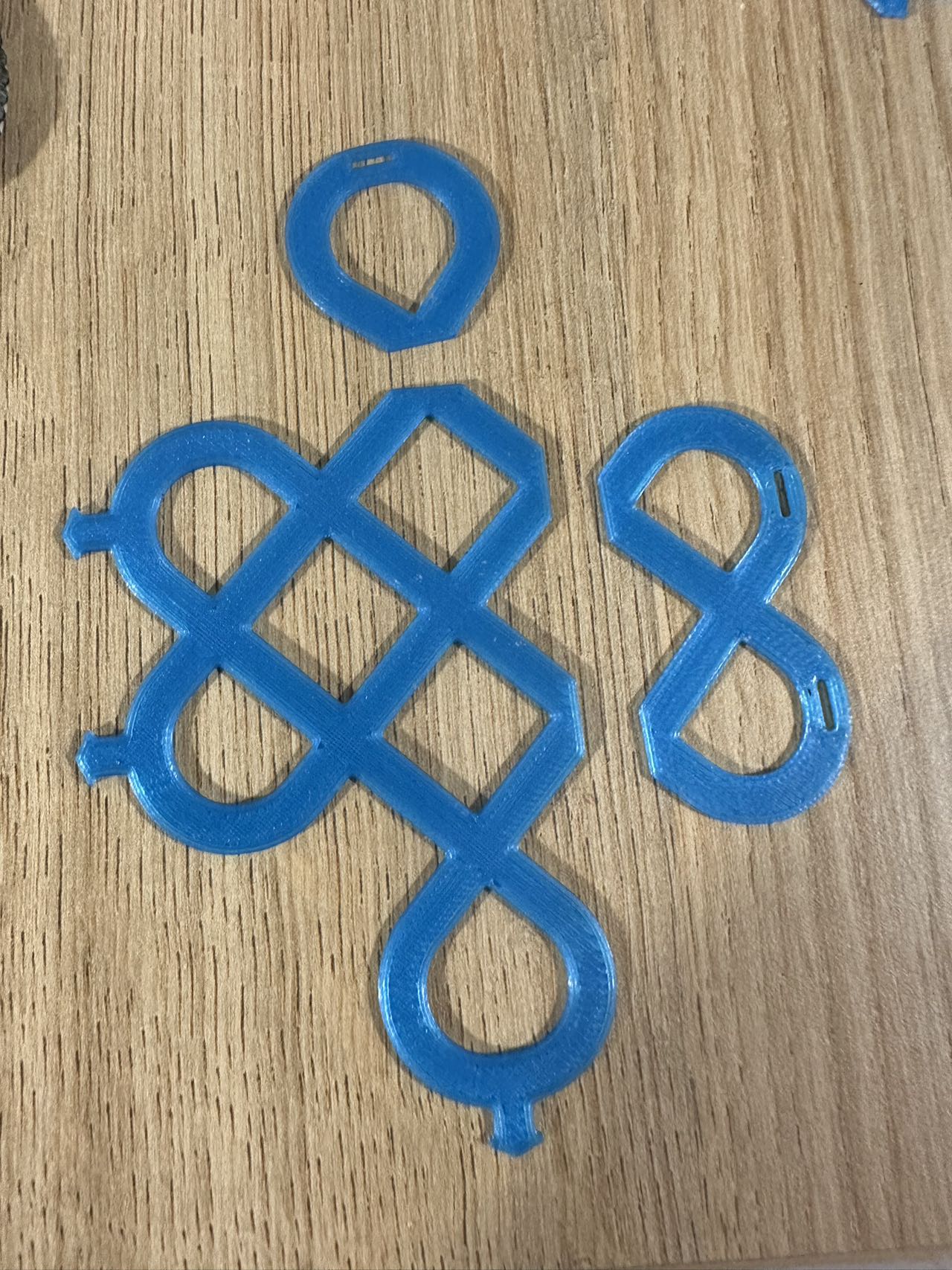

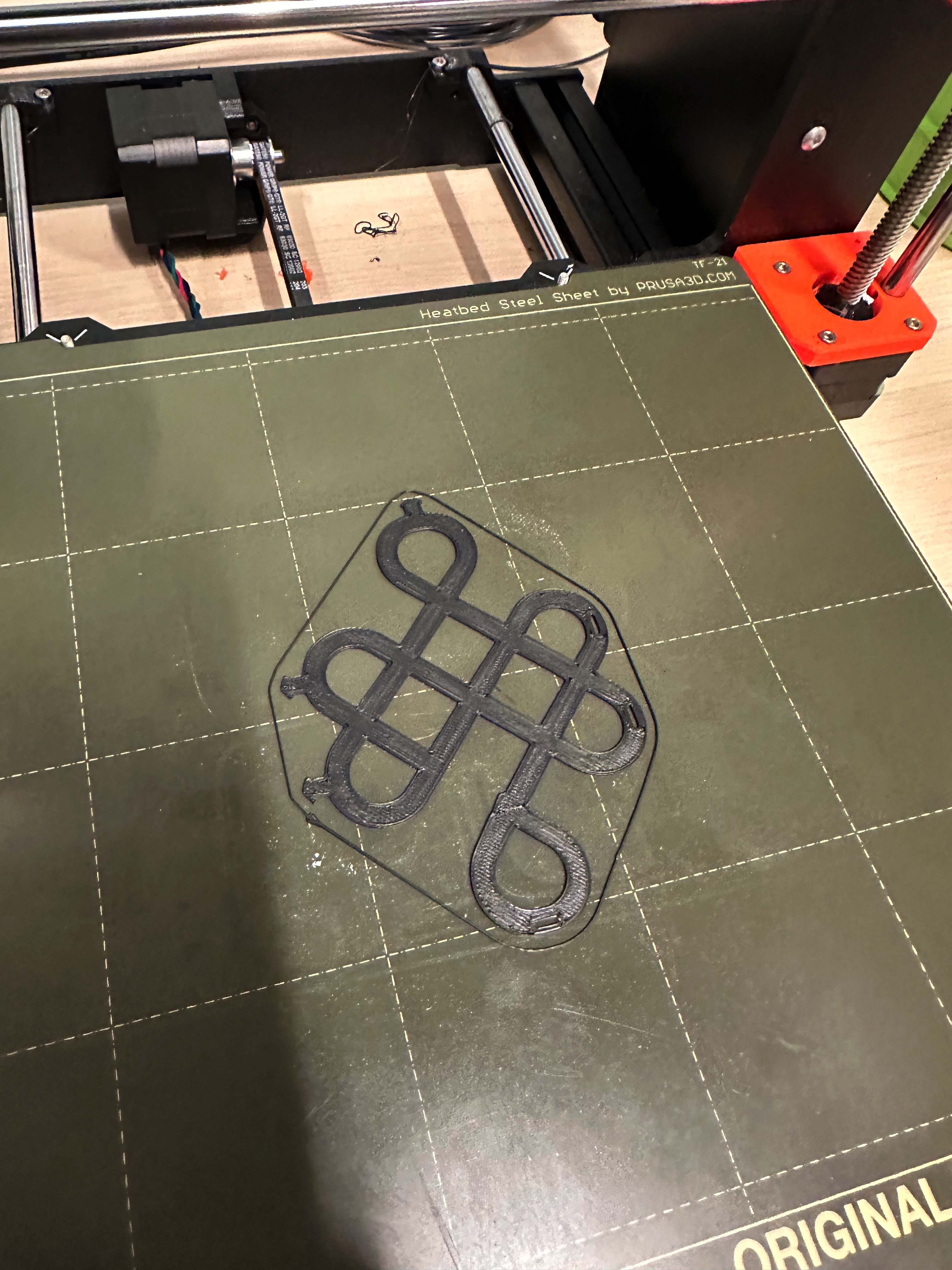

I tried to print out my design to see how it works and I used red PLA material to print. The design really worked even though there are lotta problems.

Problems

There are 2 main problems.

The first is the connections don’t work perfectly. Once I linked them together I could never pull out the arrows from the slots. This may be caused by the shape of arrow(the arrow is too thick), and the hard material as well.

The second is when components are assembled together, there are angles between them which means the original surface could not be flat at all. This may be caused by the way of conneting and the hard material.

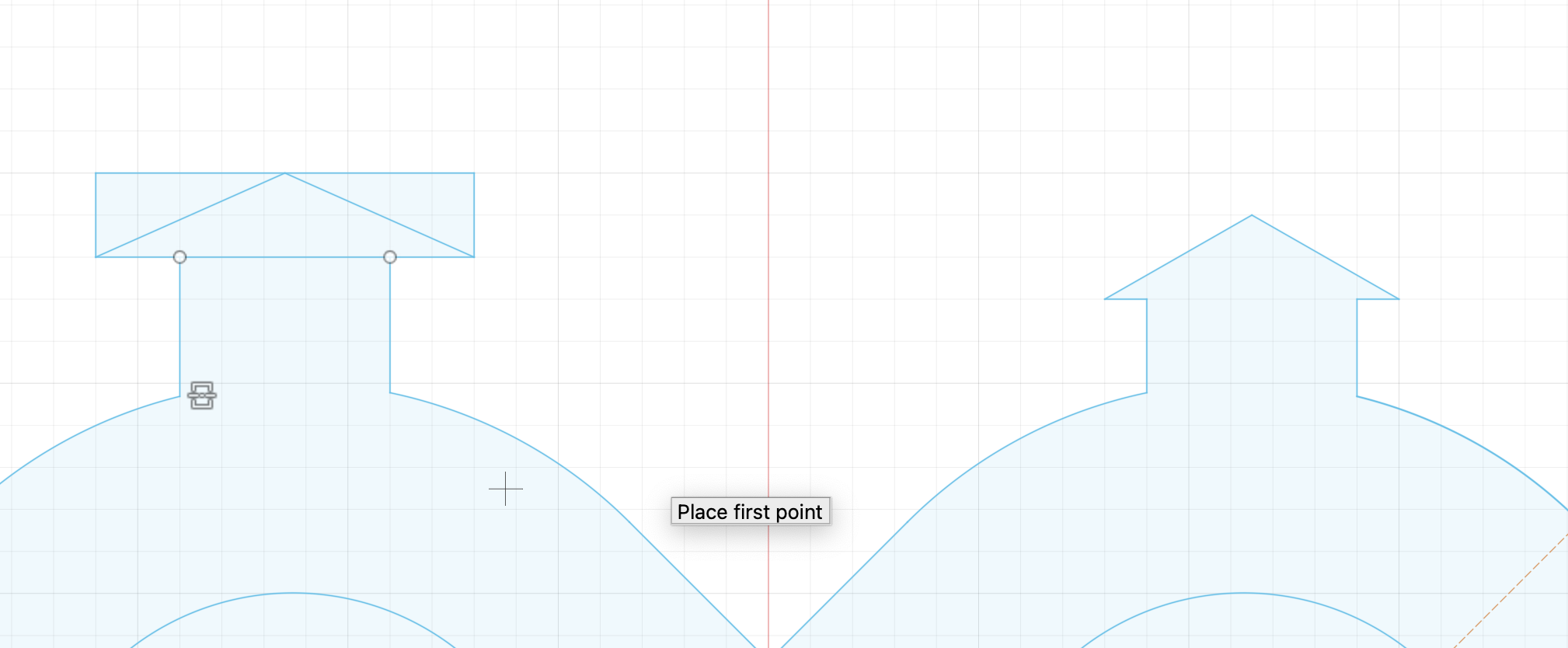

Improvements(1st Round)

Arrows&Slots

I made the arrows thinner to unable them to be removed from the slots. Also I made the slots wider a little bit.

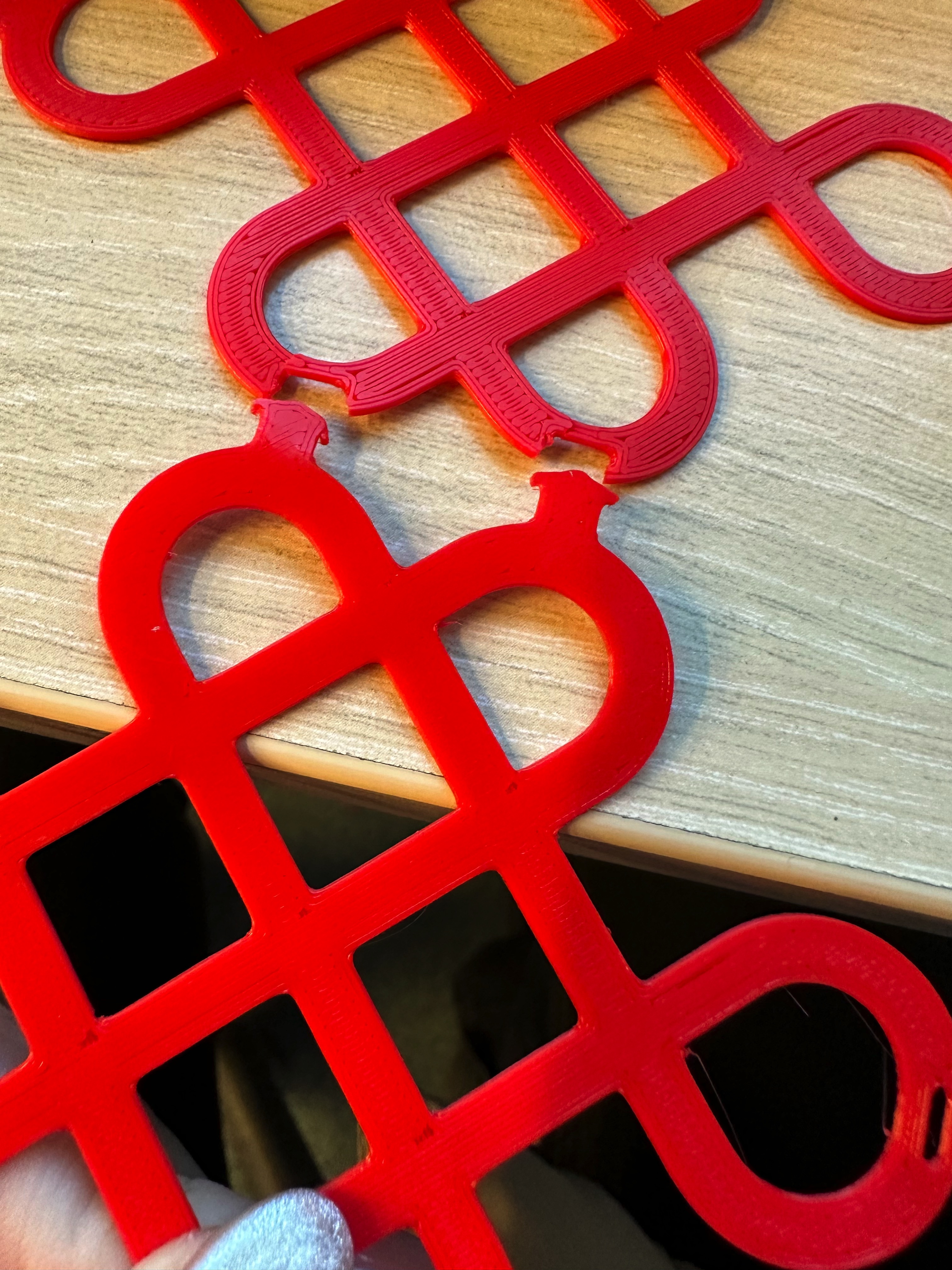

Flexibility

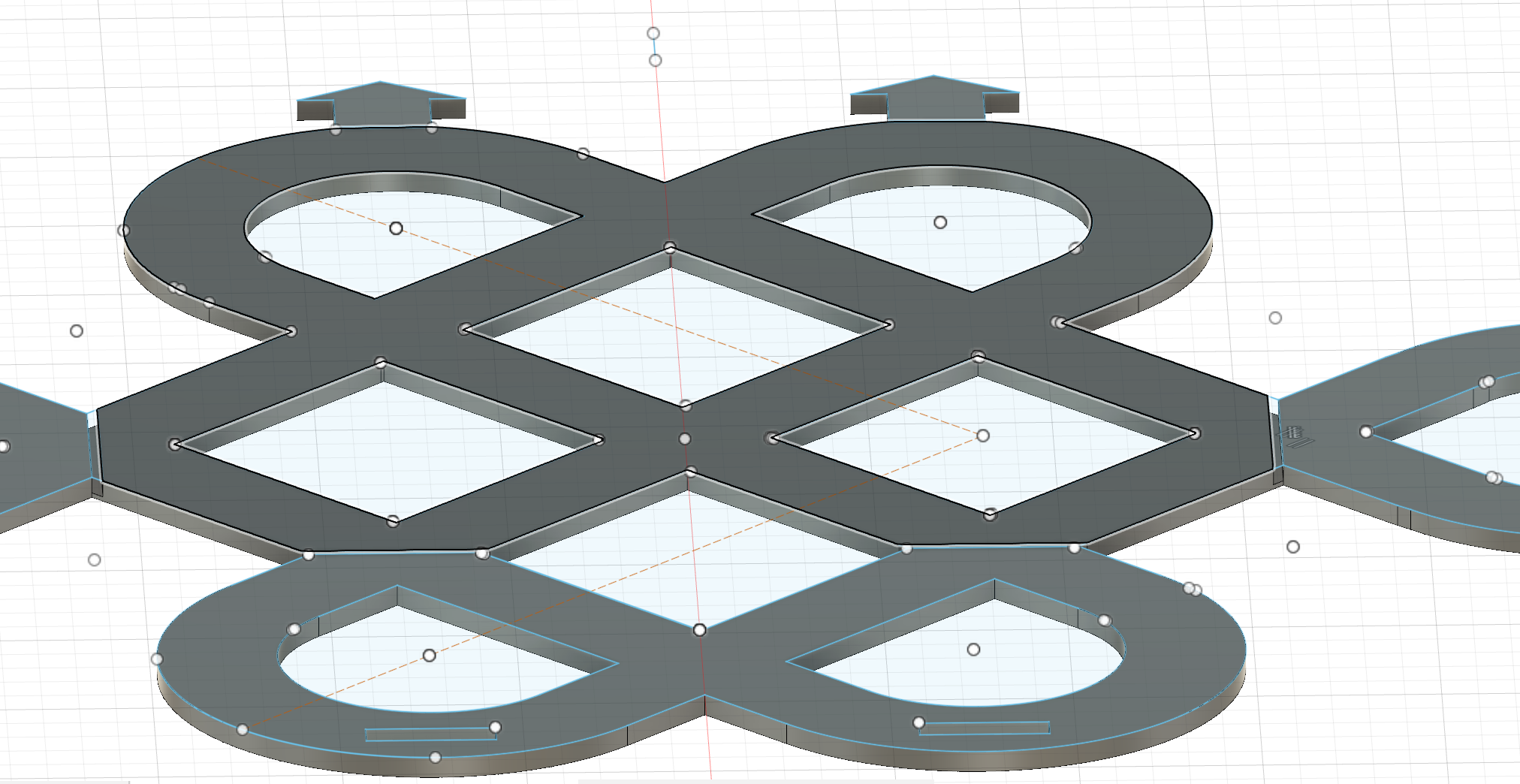

I tried to make components more flexible and foldable by making part of components thinner.

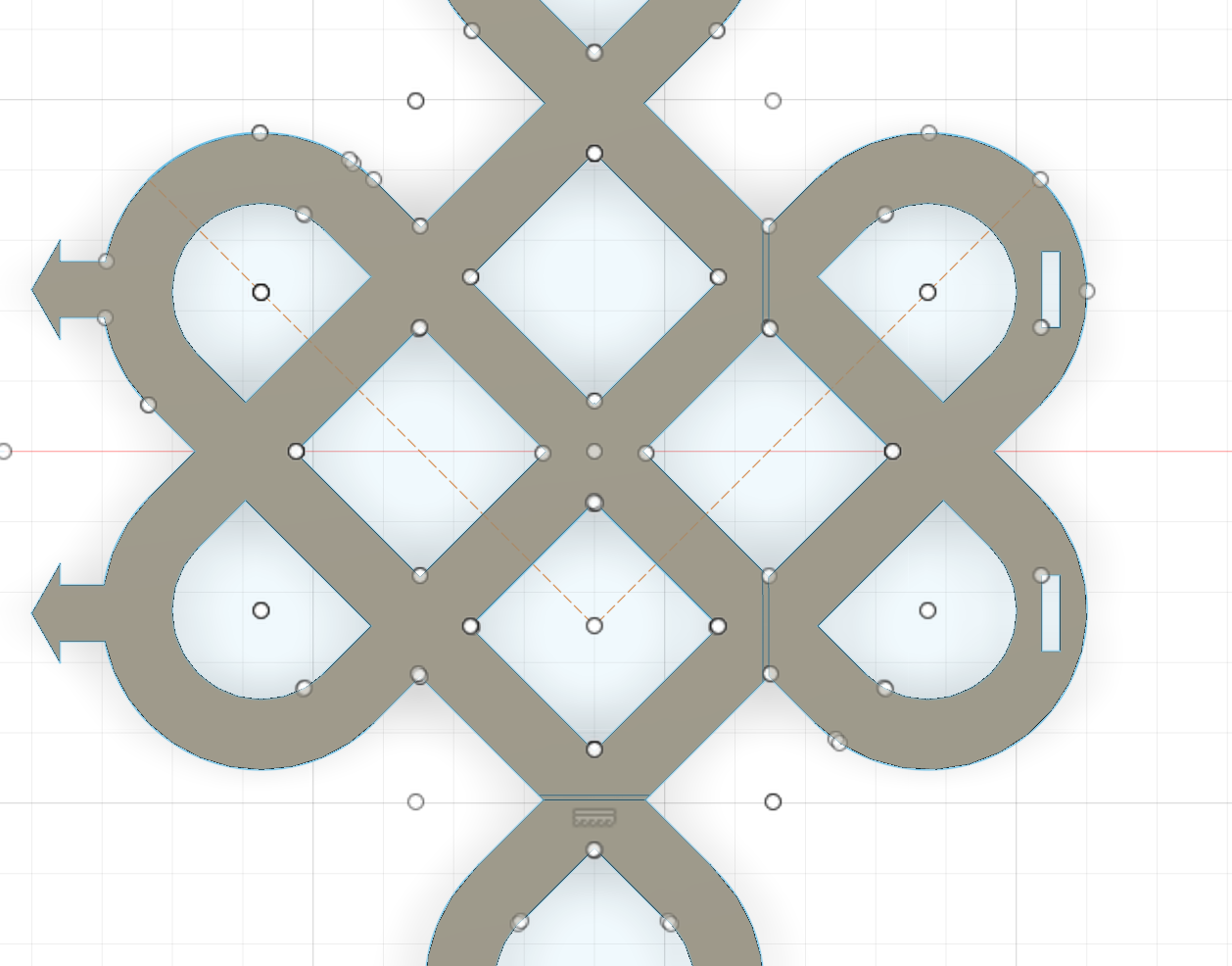

So I cut some lines on the components and extruded them inside to let the selected part to be 0.6mm thinner(the left will be 0.2mm thick).

New Problem

The connections worked better now as they could be taken apart. But the thinner parts failed. The layer was too thin to link different parts together and it broke as it’s removed from the plateau.

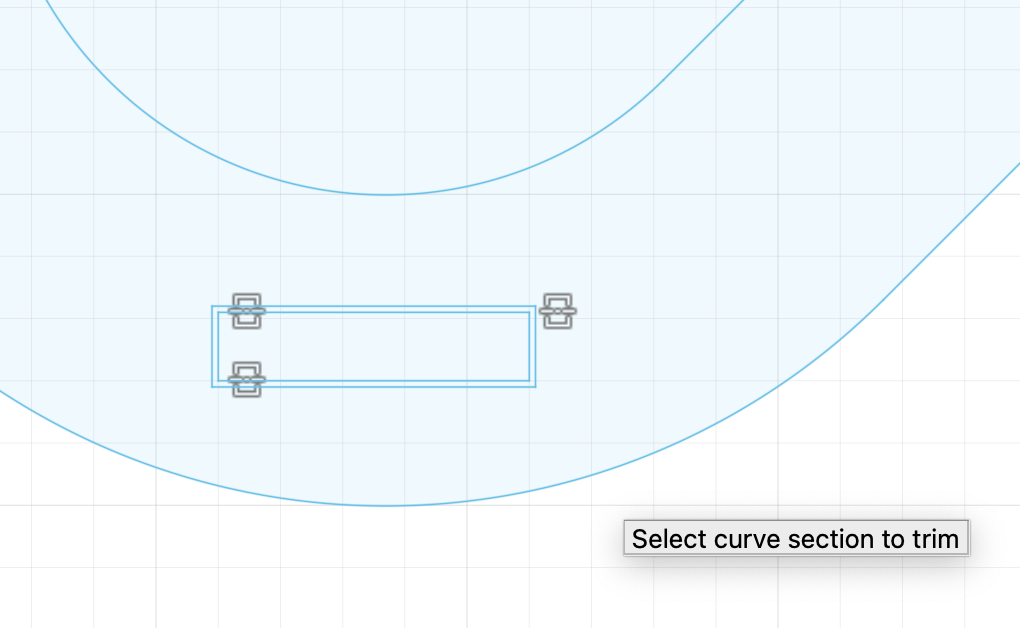

Improvements(2nd Round)

Intrude

I Intruded the thinner parts less this time with only 0.4mm. And the overall components would be 0.8mm thick, the connectiong layer will be 0.4mm.

Material

Nevertheless, I change the material from PLA into PHA to gain a more softer effect. Finally it worked!

Next Steps

I plan to improve the pattern to be more artistic(but I have no idea yet), also try some new ways to press-fit the components.